11/3/10

Tungsten sub-oxides nanowires

Do you like this story?

Transition metal oxides are a large family of materials that show any interesting properties such as superconductivity, colossal magneto resistance, and piezoelectricity. Nanosized transition metal oxides, because of their huge surface areas, are promising candidates for a vast range of applications including lithium-ion batteries catalysts, electro chromic materials and sensors.

Nanotungsten sub-oxides

Tungsten trioxide nanomaterials have potential use as electro chromic, gas sensing and photo catalyst materials. The doped and undoped tungsten oxide nanowires can be synthesized using either tungsten foils or powders as sources.Nanotungsten sub-oxides

Nanotungsten sub-oxides have high aspect ratios and promising physical properties as compared to the corresponding bulk compounds, particularly, W18O49 nanowire arrays exhibit excellent field-emission characteristics. Some WO3–x needle-like crystals also serve as precursors for the synthesis of WS2 nanotubes. The W5O14 phase can be converted into WS2 nanotubes in fluidized bed reactions.

Preparation

Maja Remškarand other researchers have prepared the W5O14 nanowires by an iodine (99.8 %,) transport method from 0.60 g WS2 (powder, 99%) adding 0.0678 g of NiI2 (powder, nickel (II) iodide), and 20 lL of distilled H2O. The transport reaction was run for 2–3 weeks in an evacuated silica ampoule at a pressure of 5×10–3 Pa. The material was transported from the source (hot zone at 1123 K) to the growth zone (1009 K), with a temperature gradient of 5.7 Kcm–1, by iodine in a volume fraction of 3.2 mgcm–3 that was used as the transport agent to produce nanowires.

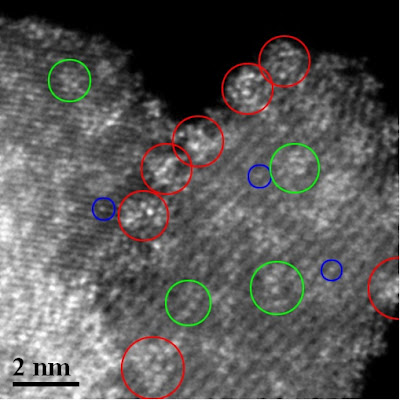

Hong Goo Choi and others have adopted a simple process to synthesize tungsten oxide with various nanomorphologies, i.e. nanorods, nanowires, and nanosheets. The tungsten hexachloride (WCl6) was used as a raw material and the tungsten oxide nanoparticles were obtained by solvothermal treatment with solvents, i.e., ethanol, mixed solvent (ethanol+water), and water, at 200°C for 10 h. The various crystalline phases of tungsten oxide, such as monoclinic W18O49 nanorods, hexagonal WO3 platelets, and monoclinic WO3 nanosheets were synthesized by simply changing the composition of the solvent. They reported that the oxygen, which was contained in water, played an important role in the final tungsten oxide phase. Especially, W18O49 nanorods grew to nanowires as the concentration of WCl6 was decreased. Using this simple process, it will be possible to control the crystalline phase and morphologies of nanostructured tungsten oxide system. Zongwen Liu and others prepared Tungsten oxide nanowires by heating a tiny tungsten wire partly wrapped with melted born oxide (B2O3) vitreous powder at 1600 °C in nitrogen atmosphere. The nanowires exhibited a well crystallized one-dimensional structure with 10–30 nm in diameter and 2–5 μm in length. A monoclinic crystalline structure was established by high-resolution transmission electron microscopy study.

Haitao Zhang and others reported on the selective growth of tungsten oxide nanowires using a vapor-solid (VS) process without the assistance of any catalysts. To achieve selective growth, low vapor super saturation was employed to suppress the spontaneous nucleation of tungsten oxide during the VS process, and patterned tungsten coating was introduced to provide seed nuclei, which promoted the growth of tungsten oxide nanowires and controlled their growth sites. Patterned tungsten oxide nanowire arrays were fabricated using simple patterning methods, such as shadow mask and laser-induced nanograting growth.

Yi Zheng Jin and others made a systematic study on large-scale production of highly crystalline W18O49 nanoneedles with high aspect ratios using a simple tungsten metal reacting with water at 800−1000 °C. By altering the W source and other experimental conditions, they have generated W18O49 crystals with diverse morphologies, and needles with desired dimensions.

Subscribe to:

Post Comments (Atom)

0 Responses to “Tungsten sub-oxides nanowires”

Post a Comment